It is a known fact that hydrogen carries around 120 megajoules of energy every kilogram, which is roughly triple the punch of gasoline. Still, producing it without having carbon emissions still hinges on squeezing every last electron by way of water.

The global electrolyzer capacity had gone on to double to 1.4 gigawatts in 2023; however, the International Energy Agency (IEA) opines that the world requires 560 gigawatts by the end of this decade in order to meet the net zero objectives. This kind of gap keeps Chemist awake all night. Heng Liu from the Tohoku University gave one of the reasons to sleep better. His team has gone on to report a cobalt-molybdenum catalyst, which turns almost every electron into hydrogen.

The precatalyst has gone on to set the stage

It is worth noting that many industrial catalysts begin life as a pre-catalyst, which happens to reshape under voltage. This makeover, which is called reconstruction, can raise or even wreck performance.

According to Liu, it is really hard to design a catalyst that works well when that catalyst itself can alter. He did note the barrier of hitting a moving target. His group decided to go through with the charge rather than fight it.

Apparently, when an electrode drives electrolysis, water molecules happen to split into hydrogen as well as oxygen. The half reaction that releases hydrogen is what is referred to as the hydrogen evolution reaction.

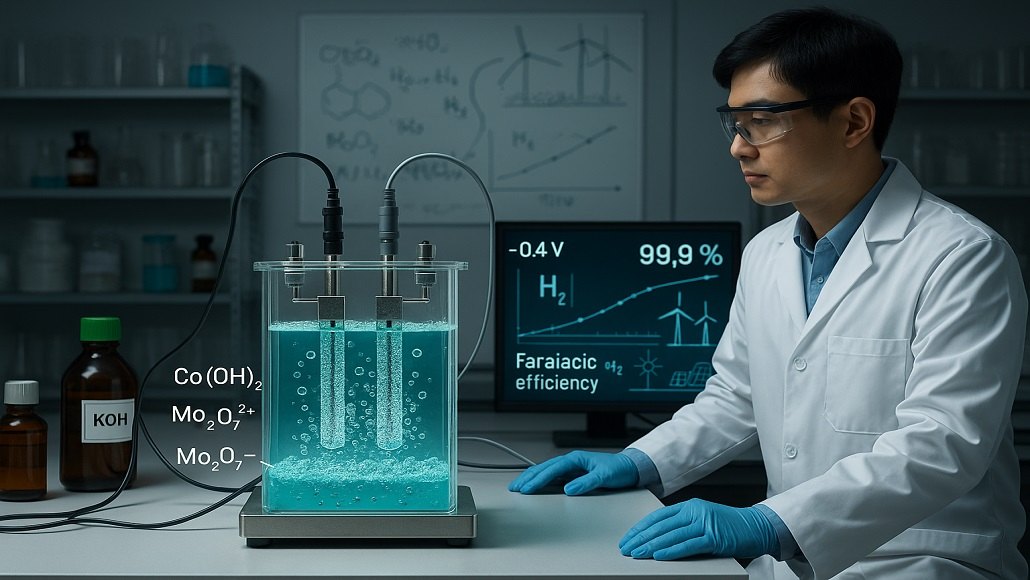

During this very reaction, Liu’s Co2Mo308 precursor, which happens to be cobalt-rich, sheds molybdenum into liquid. The exposed cobalt atoms then bind the hydroxide ions together and reorganize into a nanoscale Co(OH)₂ shell.

Cobalt along with clean hydrogen

It is worth noting that cobalt holds a very sweet spot when it comes to the periodic table in terms of catalytic activity. It happens to have the right balance of electron density so as to attract as well as spill out protons during the production of hydrogen.

When together, the cobalt-molybdenum catalyst happens to form a conducive as well as balanced surface, which resists corrosion with alkaline solutions. This kind of durability is indeed essential for keeping the large electrolysis run without any kind of constant and consistent maintenance.

Notably, voltage control lets the shell wrap the crystal core in an even way, thereby creating a very tidy heterostructure. Laboratory tests showcase the interface speeds up the step wherein water donates its first proton.

Meanwhile, molybdate anions, which are dissolved, drift back and perch onto the shell. At certain slightly more negative potentials, they pair up as Mo₂O₇²⁻, therefore loosening the hydrogen grip and letting the bubbles spill out much faster.

Molybdate ions along with clean hydrogen

The presence of MoO₄²⁻, which is the molybdate anion, as well as Mo₂O₇²⁻ ions, should not be regarded as just a side effect of the reconstruction process, but it plays a very direct role when it comes to performance.

Interestingly, these ions alter the way hydrogen sticks and leaves the surface, which is indeed the key to keeping the reaction efficient as well as fast.

Apparently when Mo₂O₇²⁻ goes on to form under slightly more negative voltage, it does encourage weaker hydrogen binding. This therefore makes it much easier for hydrogen atoms to team up and detach as gas as compared to staying stuck onto the surface.

The fact is that the Faradaic efficiency happens to measure what fraction of the present produces the desired product. The new catalyst happens to reach almost 99.9% at -0.4 volts, as opposed to the reversible hydrogen electrode having a hydrogen output of 1.85 moles every hour.

These numbers hold for more than a month at around 100 milliamps every square centimeter, which is the current density relevant to the alkaline industrial cells.

Notably, commercial platinum on carbon electrodes within the same test lost 3/4 in terms of their activity within a day.

Right from the lab bench to the factory floor

The study went on to show that the material keeps working after sitting on the shelf for even weeks. This kind of balance lowers the shipping as well as storage costs when it comes to large-scale projects. Cobalt, along with molybdenum, happens to be already mined for batteries as well as steel, and hence the supply chains do exist. Still, recycling plans will be required in order to prevent certain price hikes if the demand climbs steeply.

Analysts go on to expect the hydrogen electrolyzer market to take a leap from $1.75 billion in 2025 to $40 billion by 2032 with an unprecedented 56% annual growth rate. The near-perfect catalysts like the one from Liu’s could even help those projections stick.

Challenges when it comes to clean hydrogen scaling

It is well to be noted that scale-up still happens to face challenges, like heat management along with electrode fouling. The Tohoku group looks forward to pilot studies that team their catalysts along with intermittent wind power throughout the Japanese Pacific coast.

Although there is a separate challenge that lies in the sourcing of alkaline electrolytes at the volumes that the gigawatt systems demand. Recycling the potassium hydroxide and, along with it, recapturing stray molybdenum are going to be a brief of engineering.

Apparently, there are researchers outside the project who welcome the mechanistic insights. By way of tracking both solid surfaces along with the changing liquid, the team has highlighted that chemistry never happens in isolation. Interestingly, every efficiency gain or cut in electricity bills is the biggest cost when it comes to green hydrogen. This is the reason why a single decimal point goes far beyond the laboratory.

Altering the hydrogen infrastructure

If, in case it scales successfully, this catalyst can lower the cost when it comes to producing hydrogen by way of cutting energy waste as well as extending the life of the equipment. That kind of savings goes on to make on-site hydrogen generation a more practical option for industries such as steelmaking, shipping, and even fertilizers. It also opens the doors for certain smaller as well as distributed electrolyzer units that could even plug directly into local solar or wind farms.

Notably, more localized production would go on to mean less dependence when it comes to pipelines as well as cryogenic transport, thereby making the hydrogen supply chain as seamless as it can be.