In a scenario to have a decarbonized future, hydrogen has gone on to emerge as a promising clean fuel. However, in spite of its potential to power industries as well as transport without emissions, sustainable hydrogen production goes on to face a major hurdle, which is the high cost and scarcity of iridium.

The Rice University researchers have gone on to develop a new catalyst reducing iridium use in proton exchange membrane (PEM) electrolyzers by more than 80%.

The breakthrough could also go on to make green hydrogen production much more affordable as well as scalable.

According to the associate professor of chemical and biomolecular engineering at Rice, Haotian Wang, this is indeed a major step toward making green hydrogen much more accessible and also scalable. He adds that through reducing iridium use by more than 80%, they are addressing one of the biggest economic as well as supply chain bottlenecks that exists in the hydrogen economy.

It is well to be noted that the present PEM electrolyzers depend quite heavily on iridium, which happens to be one of the few metals that can take into account the harsh acidic environment of water splitting. However, iridium happens to be among the rarest elements on Earth, which costs almost $160 per gram.

Without even decreasing the iridium consumption, the forecasted demand from electrolyzers alone could go beyond 75% of the annual supply of the world, opined Haotian Wang. This is simply not sustainable if one is serious in terms of scaling the hydrogen production.

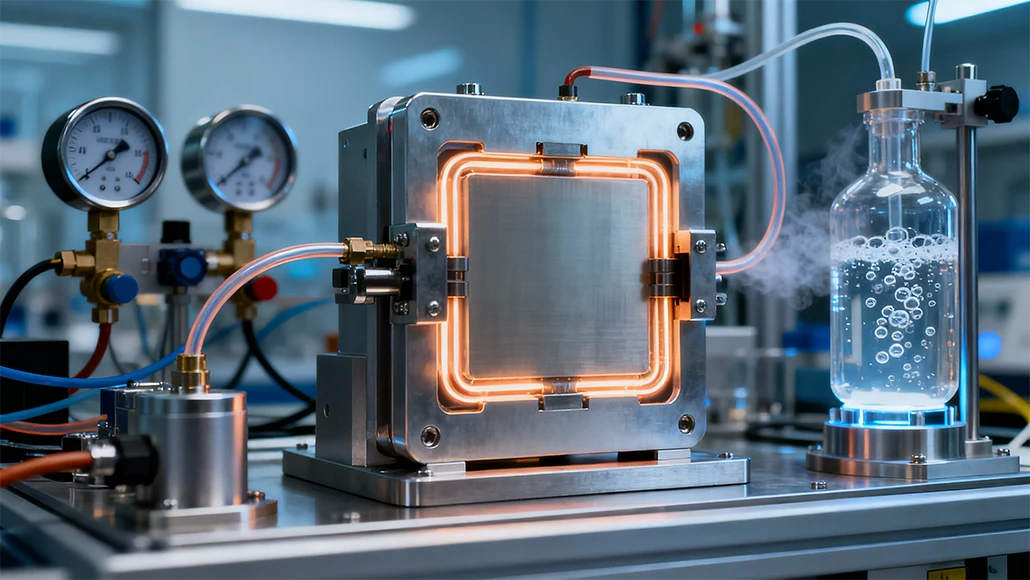

In order to solve this, the Rice team went on to design a catalyst where iridium atoms get embedded in a ruthenium oxide lattice rather than coating the surface.

Working alongside De Nora Tech, they made use of density functional theory and also Monte Carlo simulations so as to forecast the optimal atomic arrangement.

As per associate professor of chemical and biomolecular engineering at Rice, Thomas Senftle, the simulations went on to reveal that iridium atoms within the subsurface layer happen to play a very major role. They help in protecting the ruthenium atoms above them from getting dissolved under extreme electrochemical conditions.

The industrial-grade performance

It is well to be noted that the team went ahead and synthesized a material called Ru₆IrOₓ, that features a six-to-one ratio of ruthenium to iridium.

It sustained an industrial-level current density of 2 amperes for every square centimeter for over 1,500 hours with minimal degradation.

Senftle says that the key is going ahead and attaining a standard iridium distribution all across the ruthenium oxide structure. That uniformity happens to promote stability since the iridium helps to stabilize the neighboring ruthenium atoms within the oxide lattice.

De Nora Tech’s industrial testing confirmed the performance of the catalyst. Within a 25-square-centimeter PEM electrolyzer, the Rice-designed catalyst went on to match the activity of pure iridium systems while at the same time using a fraction of the metal.

Wang says that their results show that they don’t need iridium-rich catalysts so as to achieve durability. This kind of opens the door to mass production when it comes to cost-effective and high-performance PEM electrolyzers.

Economic and scientific effect

One of the economic evaluations ascertained that replacing the standard iridium oxide having Ru₆IrOₓ could decrease the anode catalyst costs by more than 80%. The design also decreases the exposure to price swings within iridium.

Beyond the expenditure, the study goes on to offer a new paradigm when it comes to catalyst engineering, stabilizing the materials from within and not coating them for protection.

As per Senftle, this work goes on to underscore how theory as well as experiment can work hand in glove. Through combining atomic-scale simulations along with stringent experimental testing, they have been able to pinpoint how a small amount of iridium can go on to balance the overall oxide lattice.

The research, which happens to be supported by the Welch Foundation, the Packard Foundation, and the National Science Foundation, could help to speed up the adoption of global hydrogen. If one can make the electrolyzers cheaper, more durable, and, at the same time, less dependent on scarce materials, hydrogen can go on to become an absolutely global and renewable fuel, said Wang.